CCT’s coating operation utilizes slot die coating heads capable of precise coat weight control. Our capabilities include (melting) hot-melt adhesive products, solvent-based adhesives, and coatings. Critical aspects of the process include coat weight, line speeds, oven temperatures, and air flow which are governed by industry standard process controls. CCT’s team must adhere to, including staging raw materials, applying adhesive to the substrate, and winding the product, all while regularly inspecting throughout.

Precise Tape Coating

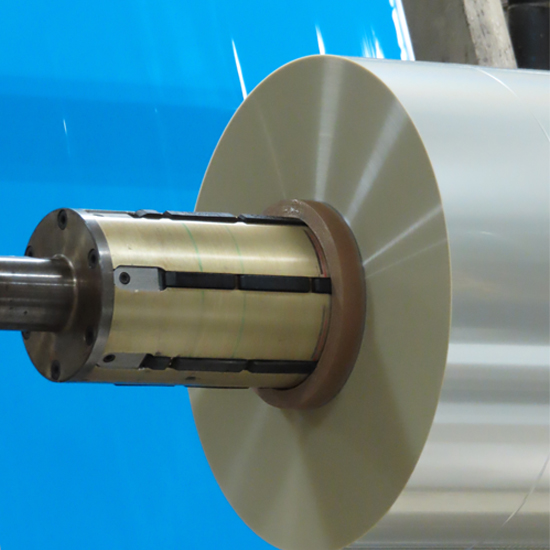

Adhesive Tape Slitting

CCT’s converting capabilities include edge trimming down to 0.25” slit widths. With several machines built to handle a wide range of substrates and face stocks, CCT offers a variety of slitting techniques. Conventional and custom roll lengths can be tailored to your specific requirements as well. We continually invest in newer equipment to take advantage of the latest manufacturing techniques—offering better tolerances, reproducibility, and lower operating costs.

1 Million+ Spooling Options

Spooled tape increases productivity and efficiency by reducing changeover through longer rolls”. There are several aspects of CCT’s converting operation that our skilled production team manages, including spooling equipment for industrial adhesive tape – films, foams, and tissues. Material can be spooled from 0.164″ to 1.125″ with spool widths from 6″ to 19″, outer diameter up to 36″, and roll length in excess of 12,000′.